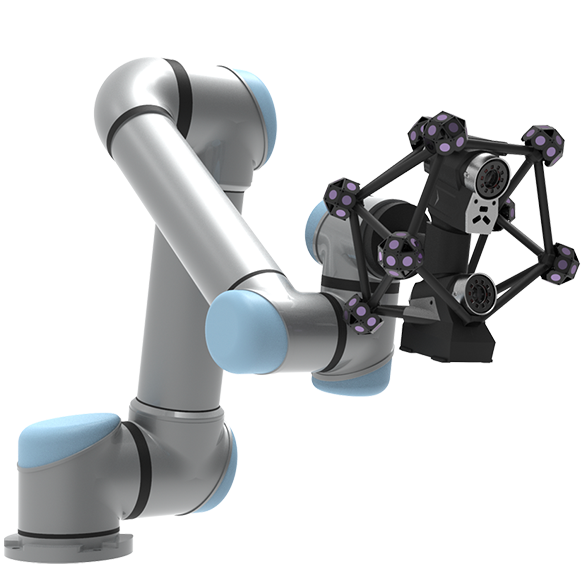

Reduce labor costs

Fully automated without manpower involvement.

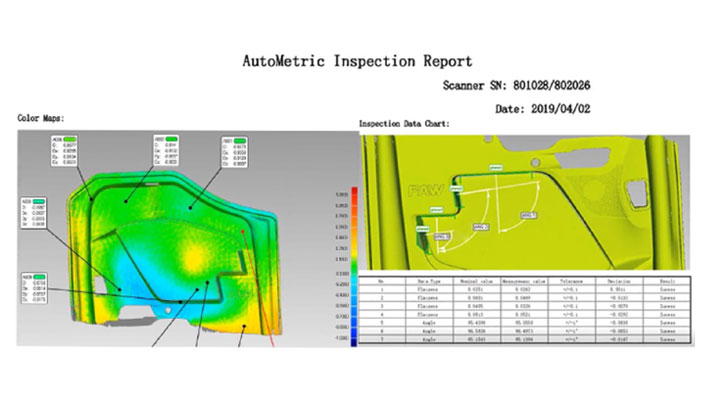

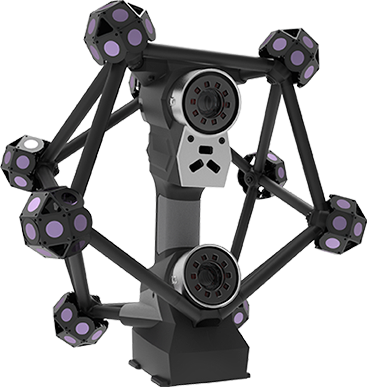

Efficiency Inspection Solution

Automatic quality inspection and delivery inspection report, which greatly enhancement of measuring efficiency compared with the traditional manual measurment.

Inline quality control

integrate measurement into automation in production line directly to improve control quality efficiently.

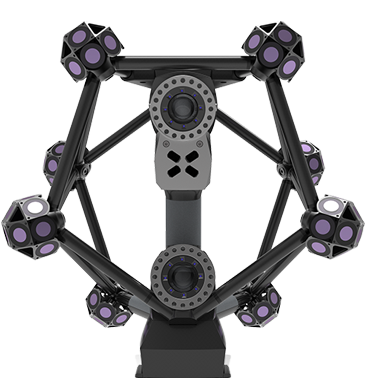

Amazing adaptability

The influence of complex factors such as workshop vibration,noise, temperature, dust, etc.can be ignored.