Intelligent Guidance Module

Just one simple click the button, all the scanning parameter will be set automatically without any concerns.

High Efficiency

High Adaptability

Accuracy up to 0.03mm

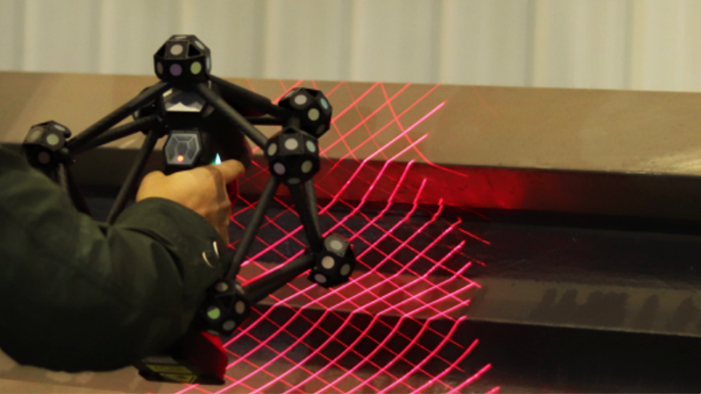

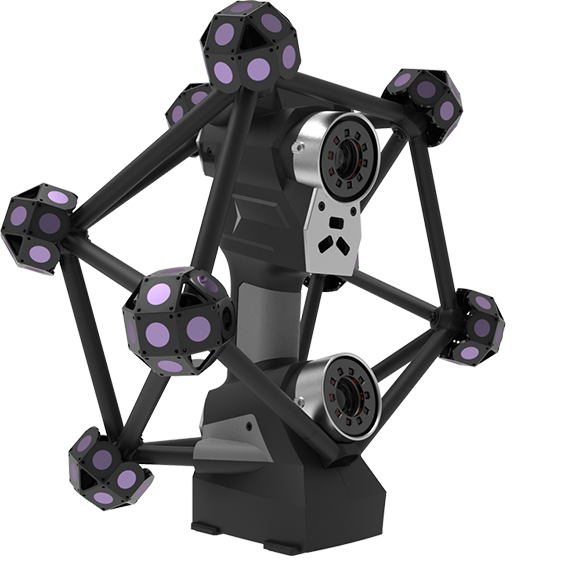

Hybrid Scanning Mode

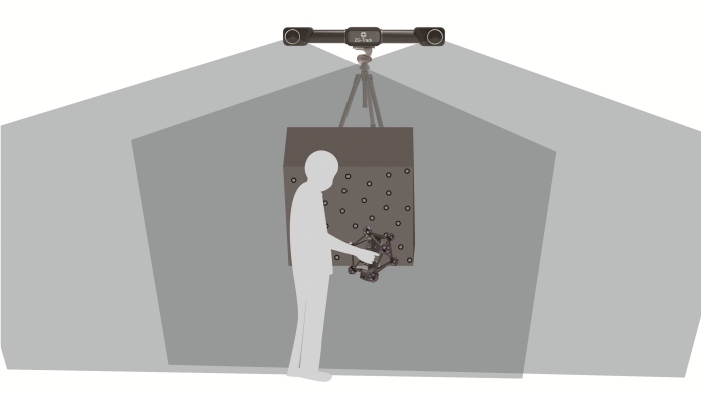

Self-positioning Technology

Wireless Operation

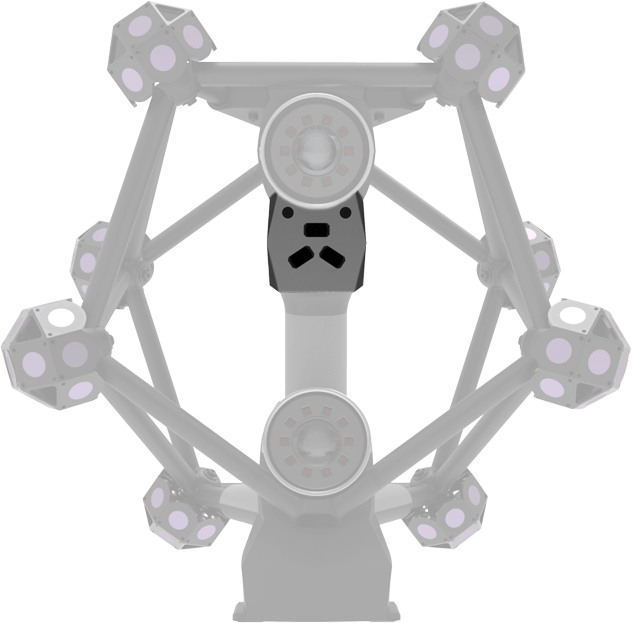

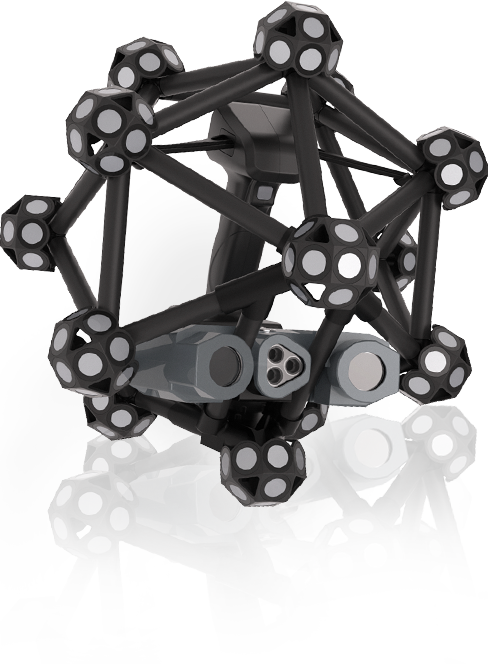

26 laser lines + 1 extra line for hard reach area

MEASUREMENT RATE up to 1,340,000 measurements/s

No need to attach markers, which can save a lot of time and improve work efficiency;

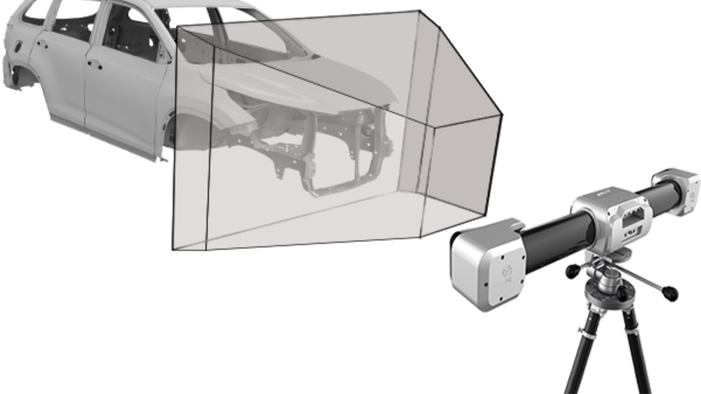

Especially suitable for fast and efficient scanning of large workpieces such as automobiles, heavy industry machinery parts, castings, etc.;

Work with the ZG-Track optical tracker, the measurement object can be firmly locked in a space of 17.6m³, and the user can move the scanned object in any way during the measurement process;

Multi-mode intelligent guidance, black, shiny and color surfaces can be scanned directly without any pre-processing;

Dual scanning mode, HyperScan DX supports Scanning with tracker by Self-Positioning System and Scanning without tracker by Markers-Positioning System;;

Markers-Positioning System is suitable for small space operations;

The dual scanning mode can be switched in real time through the interactive system.

With unparalleled high precision , flexibility and adaptability, ZG-Probe is fully capable for quality control,reverse engineering and assembly analysis etc. Compared with the traditional CMM, ZG-Probe can work in different & complex environment outside laboratory for stable and accurate measurement.

ZG-Probe is fully capable for quality control,reverse engineering and assembly analysis etc.

Just one simple click the button, all the scanning parameter will be set automatically without any concerns.

Built-in measurement toolbox support various dimensions and features measurements, also provide 3D comparison,data annotation and inspection report generation

To reduce the size of scan data & processing time and improve working efficiency dramatically.

Simple operation with built-in interactive buttons in scanner to choose scanning mode,calibrate and process scan data by simple buttons operations.

There is only 1.5kg of the device, small and portable, can carry to anywhere for handheld scanning.

The newly upgraded camera lens, chip and light source system make the equipment hardware performance more powerful and reliable.

It can be used in different environments, and applications for 3D modeling of the surface of different sizes of workpieces, one device with multiple functions.

The new learner without any experience can master various operations and calibration procedures after one day of training.

It can be integrated with robots, automated assembly lines, etc., to implement rapid secondary development, and realize automated scan and inspection.

red laser

1,340,000 measurements/s

up to 0.1mm

up to 0.03mm

0.064mm

0.078mm

400mm