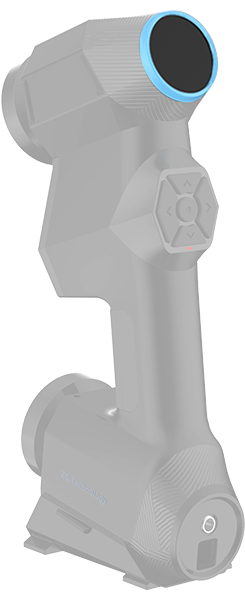

Intelligent Guidance Module

Just one simple click the button, all the scanning parameter will be set automatically without any concerns.

Blue Laser Technology

HIGH EFFICIENCY

GOOD ADAPTABILITY

Accuracy up to 0.01mm

Self-positioning Technology

Wireless Operation

0.01mm;Accuracy and resolution up to 0.01mm under fine scanning mode;

Perform fine scanning of small features to truly restore the surface details of the measured workpiece;

The accuracy of the RigelScan series has been certified by National Institute of Metrology;

Scanning area up to 600x550mm;

Measurement rate up to 1,350,000 measurements/s;

The scanning rate is 2.2 times higher than that of mainstream 7-line cross products in the market

Pure blue laser technology has stronger anti-interference, faster scanning speed, more accurate and finer data;

Blue laser technology is the key to improving scanning adaptability of the RigelScan series, enabling it to easily obtain data on dark or shiny surfaces;

Standard and fine dual scanning modes enable the scanner to switch freely between a wide range of 600mm and a high resolution of 0.02mm.

Just one simple click the button, all the scanning parameter will be set automatically without any concerns.

Built-in measurement toolbox support various dimensions and features measurements, also provide 3D comparison,data annotation and inspection report generation

To reduce the size of scan data & processing time and improve working efficiency dramatically.

Simple operation with built-in interactive buttons in scanner to choose scanning mode,calibrate and process scan data by simple buttons operations.

There is only 1.0kg of the device, small and portable, can carry to anywhere for handheld scanning.

The newly upgraded camera lens, chip and light source system make the equipment hardware performance more powerful and reliable.

It can be used in different environments, and applications for 3D modeling of the surface of different sizes of workpieces, one device with multiple functions.

The new learner without any experience can master various operations and calibration procedures after one day of training.

It has low requirements for the workshop environment, and can maintain extremely high scanning accuracy in noisy, vibration, and dusty environments.

It can be integrated with robots, automated assembly lines, etc., to implement rapid secondary development, and realize automated scan and inspection.

BLUE LASER

1,350,000 measurements/s

up to 0.02 mm

up to 0.02mm

up to 0.01mm

0.015+0.035mm/m

550mm