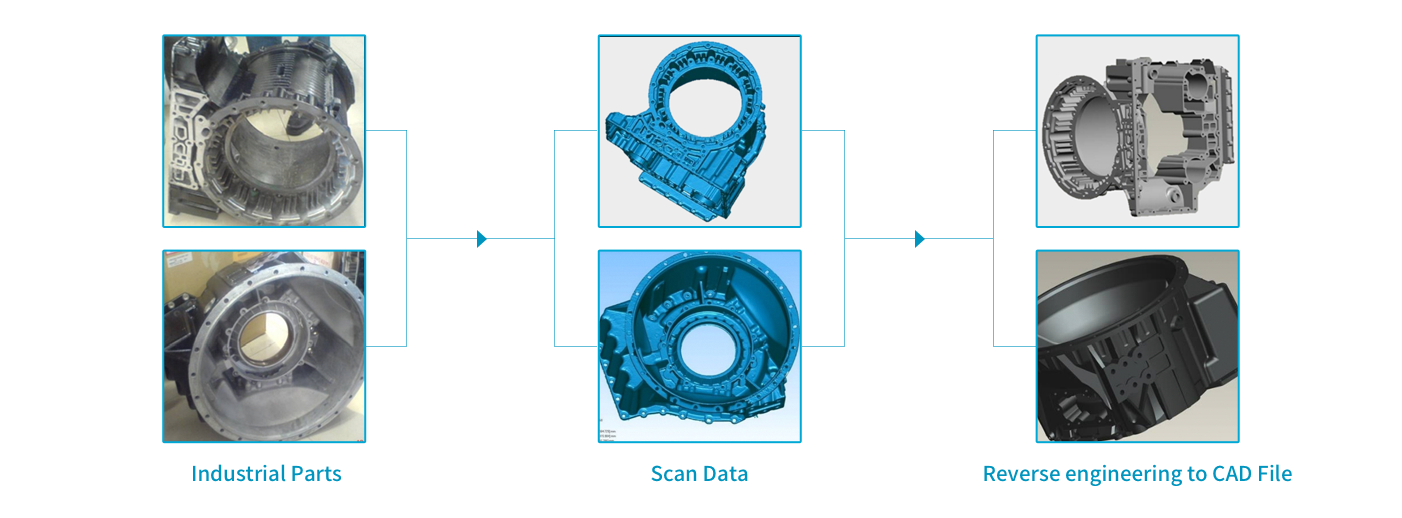

Reverse design, as the name suggests, is different from the design process. The process is to build a 3D CAD model based on scan data acquired from the surface of an existing part or product prototype. With the widespread application of machine vision technology in the manufacturing field, especially rapid development of digital measurement, it has become an important application direction of reverse engineering by adopting 3D scanning technology to obtain spatial data for product modeling design.

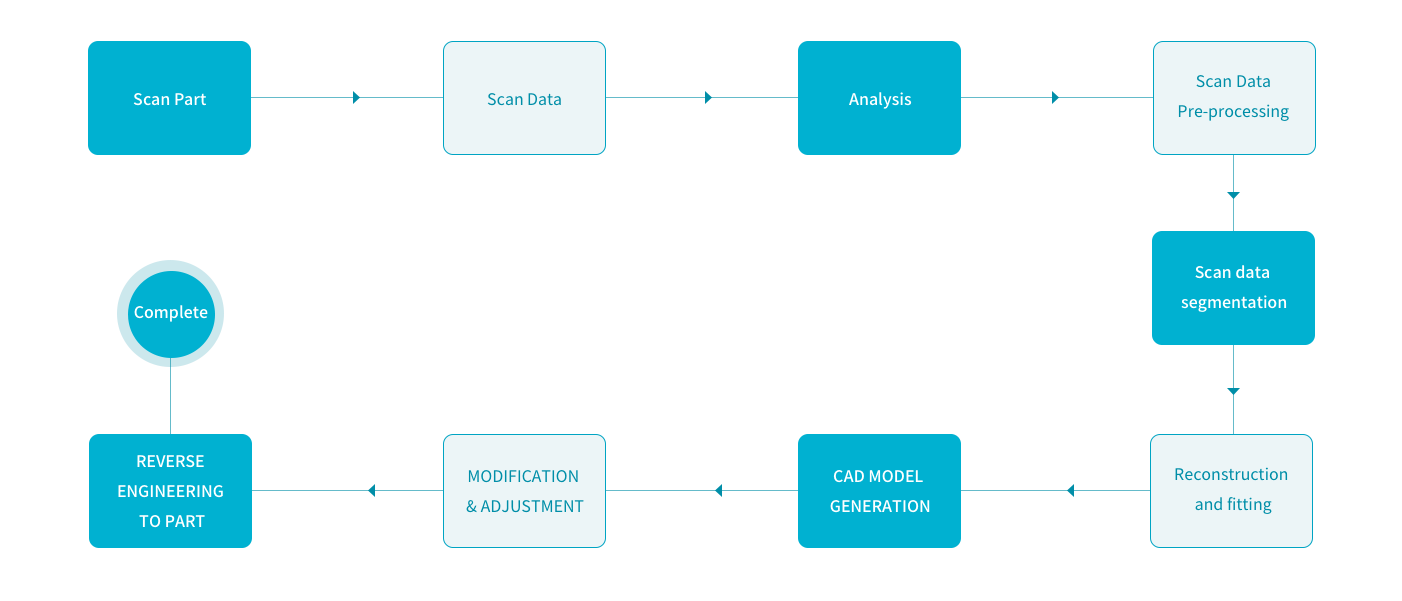

To acquire the cloud point data by adopting 3D scanner

The point cloud data is processed by the ZG software to obtain the triangular mesh data and perform coordinate changes, point cloud noise reduction, smoothing, optimization, and simplification preprocessing on STL data. The data obtained in this step can be used for 3D engraving, 3D printing, comparison analysis, etc.

Generally, we can use reverse engineering software like UG, CATIA, GEOMAGIC DX and other professional software to process the obtained triangular mesh data, which including patch fitting, cross-section creation, curve extraction and many other feature extraction methods. At this time, innovative design and optimization design can be carried out.

After a series of operations such as software calculation, extension and shearing, a reverse engineering model is obtained, which can be used for high-precision CNC machining, mold design, etc.

The above steps are a standard process step, not necessarily complete all of them. Each step has complete CAD/CAE/CAM software to finish related operations. For some applications, STL 3D data models can even be directly imported into 3D printers or CNC engraving machines for direct printing and engraving.

To shorten product design and development cycles, and speed up product upgrading

To reduce the cost and risk for new product innovation;

To improve product housing and design

Powerful reverse engineering and quality inspection software;

Heavy Industry

Aerospace

Cutural

Consumer

Casting Parts

Mould

Automotive

Medical

More Applications